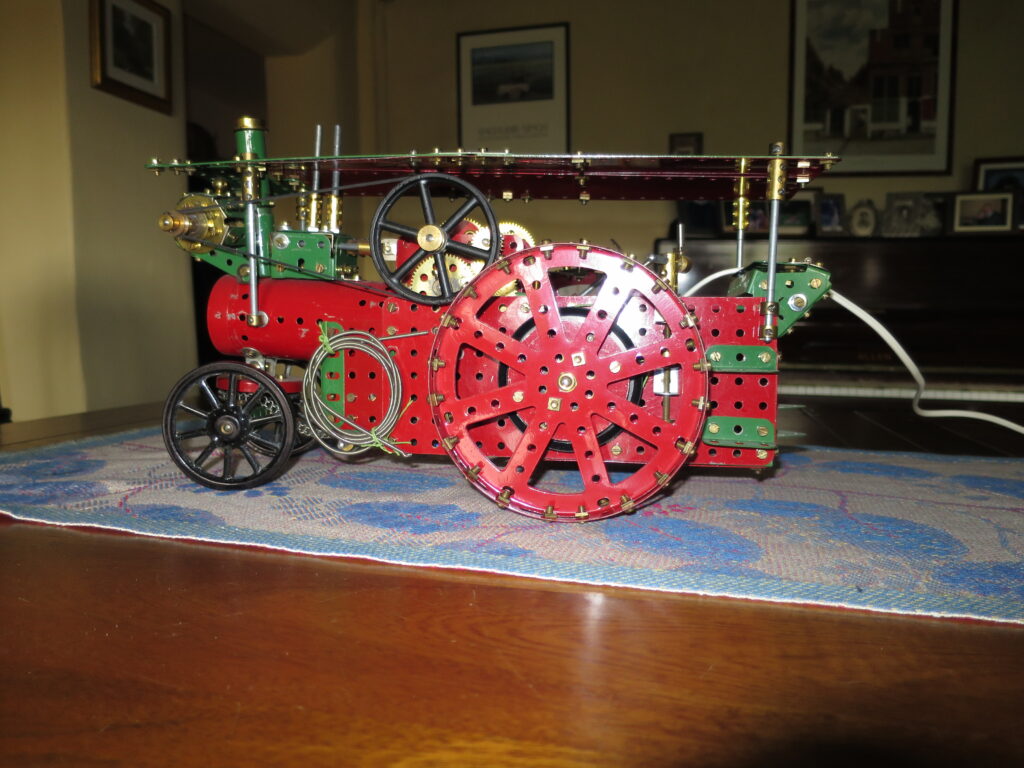

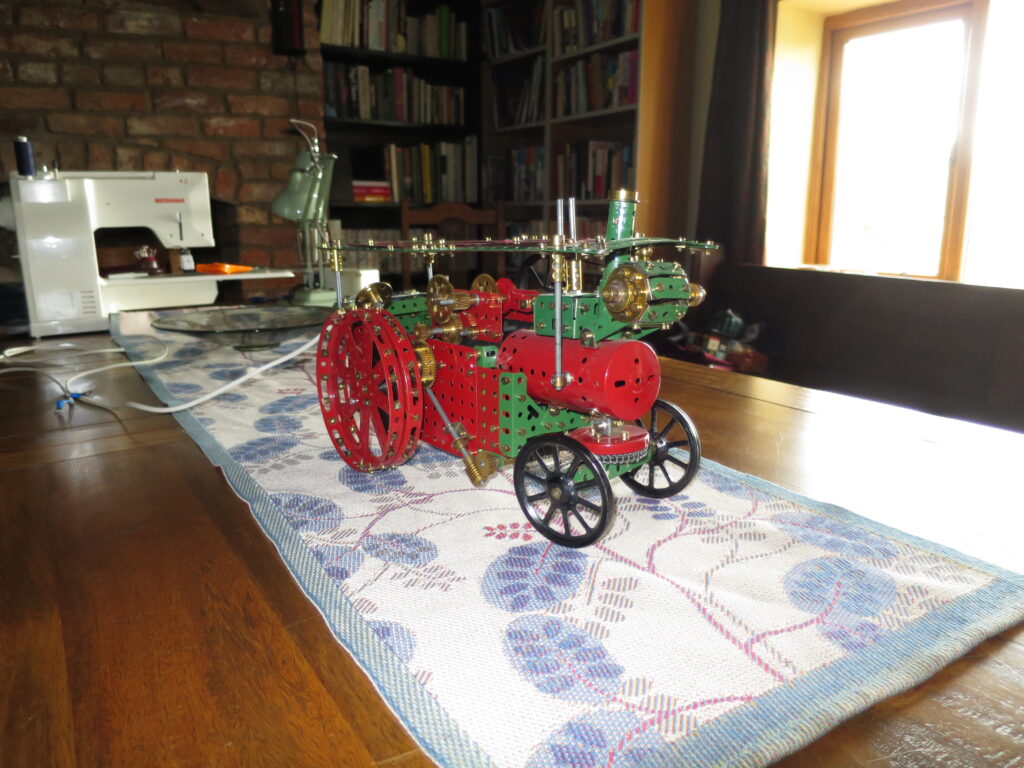

Early 2024. I’d been looking forward to building the Super Model traction engine, and it didn’t disappoint. It’s not huge, but its proportions are good, and it operates pretty well. And I wanted to put my resprayed flywheel to use.

Build notes

This one went together pretty easily. There were a number of things to fix of course, the first being that the Super Model uses a 1929-style 6 volt motor, and I’ve not got one. Instead I used an E20R 20-volt motor, and extended it upwards by an inch using a couple of 1 1/2 by 3 inch plates. I also had to widen the rear end of the model by half an inch to get the motor in. So the body was 3 1/2 inches wide at the motor rather than 3 inches, narrowing slightly to 3 inches in front of the motor, so the triangular plates join under the boiler as per the leaflet. This solution simplified the towing point as well, as all you need is a couple of trunnions. The leaflet solution is more complicated in order to get the towing point central across a 3-inch plate.

The second area I made changes in was to the cylinder block and pistons. The cylinder block is a small closed box mounted on top of the boiler, and the pistons move in and out of the block. I can’t believe anyone could get this working as described in the leaflet. It’s difficult to build the block as described, as it’s a closed box with angle brackets mounted inside it that need adjusting to get the pistons to move freely through it without hitting the end of the box. And as described there’s no way in to adjust the angle brackets, and no way to adjust the box’s position on the boiler, which you need to do, as there’s very little leeway between hitting the end of the box and disengaging from the bracket at the other end of the box. All of which will become a lot clearer if you try the build! Anyway I redesigned the cylinder block using double brackets for the pistons to run in (which are automatically lined up), and mounting the cylinder block on the boiler using just angle brackets, which gives some front to back adjustment. This meant the pistons ran smoothly…

…after I also replaced the connections at the other end of the pistons. The original design is pretty Heath-Robinson and has many points of failure. I replaced both connections with single-throw eccentrics, mounting both inside the plates I added to extend the motor sides upwards by an inch (see above). Simpler and better than the original design (and probably not practical with the original motor).

Other than that, I made minor changes to the roof so I didn’t need to bend flat girders, and that’s about it. A good model to build.