July 2024. I’ve plucked up the courage to have a go at building the second version of the Super Model Loom. I’ve been collecting parts for a while: as well as an inordinate number of 2 1/2 inch strips it also requires some special parts that haven’t been made by Meccano since WWII, and they probably never made very many in the first place:

- A shuttle (part 104). You have to have a Meccano shuttle, or a reproduction of one (which do exist). I was lucky enough to get hold of an original.

- A reed hook (part 105). This is not strictly speaking part of the model, but you need one to operate the loom. Meccano reed hooks are like hen’s teeth, but I found what looks to be a similar reed hook here. I’ve not built my loom yet, so it’s not tried and tested.

- A sand roller (part 106a). Again, I’ve never seen an original on sale. They are similar to the wood rollers (part 106), but the wood is of slightly larger diameter, and is covered with a perforated thin steel sheet like a fine cheese grater. It’s job is to grip the finished cloth as it comes off the loom, enabling it to be wound onto a wood roller. I’ve made my own, using a wood roller. I wound a strip of paper onto the roller to give it the added diameter. I bought some steel sheet (from here), cut it to size, and perforated it with a fine masonry pin (as used for picture hanging). Hundreds and hundreds of times. Then I nailed it to the roller. It looks the part, and I’m hoping it will do the job. By the way, the original Binns Road parts never had sand on them, although apparently Meccano Spain stuck sandpaper round some wood rollers at some point and sold them.

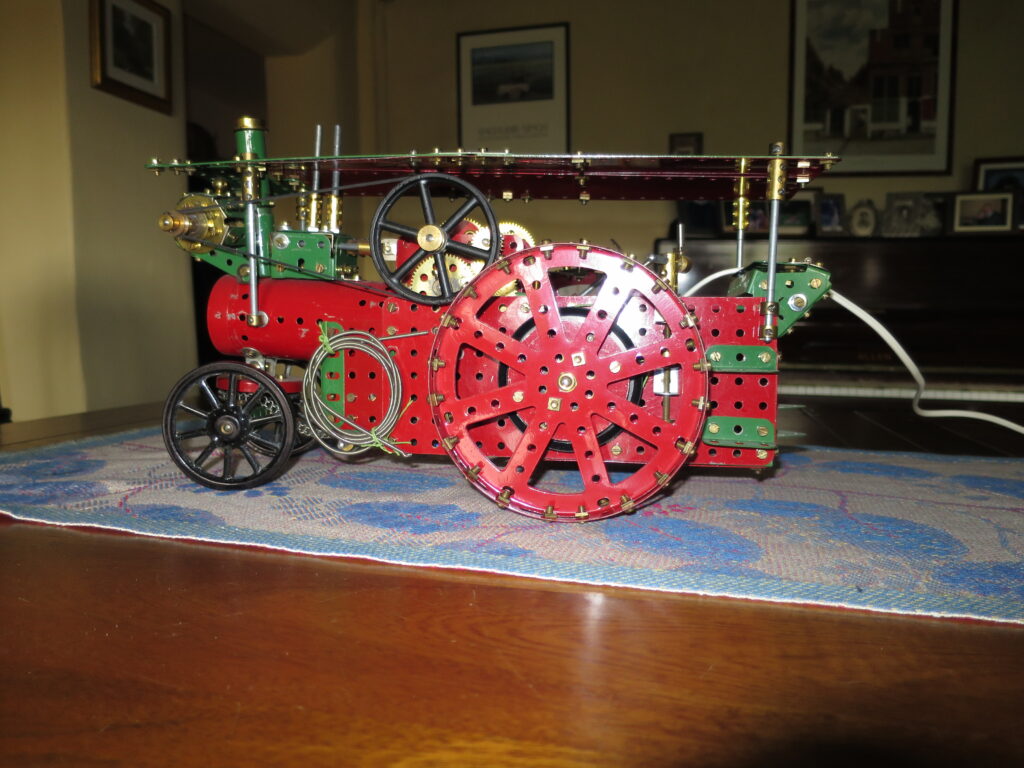

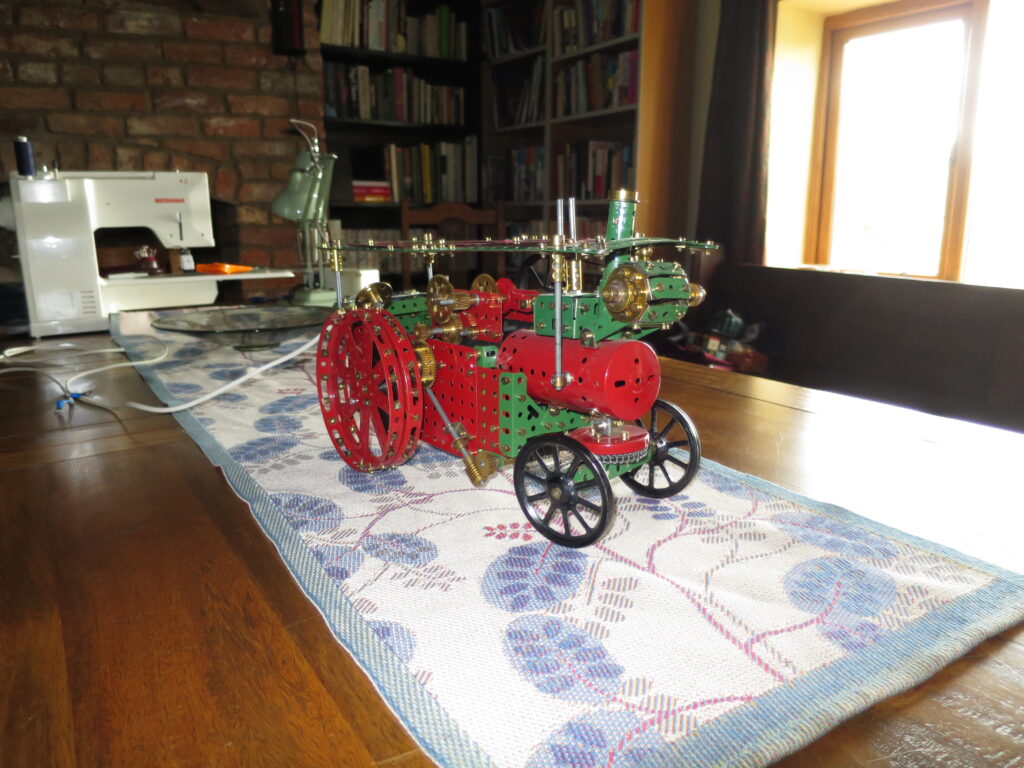

Here are photos of these parts. No loom pictures yet, as I’ve not built it!